By PXN Design Team,Posted on July 1, 2025

- The Fabric Decision That Shapes Your Collection

Choosing between knitting and woven fabrics is a foundational decision for any apparel brand. These two textile powerhouses offer distinct advantages in comfort, structure, and functionality, but the right choice depends on your design goals, target market, and performance needs. This guide breaks down their core differences to help you make an informed decision.

- Knitting: The Fabric of Flexibility & Comfort

Knitted fabrics are created by interlocking yarns into loops, resulting in natural stretch and softness. They’re ideal for designs that prioritize movement, comfort, and casual elegance.

- Core Characteristics:

– Stretchability: 4-way stretch in jerseys and rib knits adapts to body contours (perfect for activewear and loungewear).

– Lightweight Breathability: Open-loop structures like mesh or pointelle promote airflow, suitable for both summer tees and winter base layers.

– Texture Variety: From smooth single knits to textured cable knits for seasonal depth.

Best For:

🔹 Activewear: Yoga leggings, sports bras

🔹 Casual Wear: T-shirts, hoodies, dresses

🔹 Loungewear: Soft, form-fitting sets

🔹 Winter Layers: Stretch thermal tops and

sweaters

- Woven: The Fabric of Structure & Durability

Woven fabrics are made by interlacing warp and weft threads at right angles, creating stability and crispness. They excel in designs requiring shape retention, durability, and formal aesthetics.

- Core Characteristics:

– Rigidity: Tightly woven fabrics like denim or twill hold structured silhouettes (think tailored suits and outerwear).

– Durability: Strong yarn intersections make wovens resistant to wear and tear, ideal for high-use garments.

– Design Precision: Crisp edges and clean lines support intricate patterns (plaid, stripes, and jacquards).

Best For:

🔹 Formal Wear: Dress shirts, blazers, suits

🔹 Outerwear: Trench coats, denim jackets, winter parkas

🔹 Workwear: Durable trousers, utility shirts

🔹 Summer Staples: Lightweight linen/cotton blends for breathable structure

- Key Performance Factors: A Side-by-Side Comparison

|

Factor |

Knitting |

Woven |

|

Stretch |

High (4-way stretch in most knits) |

Low (unless blended with elastic fibers) |

|

Structure |

Soft, form-fitting |

Rigid, shape-retaining |

|

Durability |

Moderate (vulnerable to snagging) |

High (tightly woven fabrics resist damage) |

|

Design Flexibility |

Excels in prints and textures |

Perfect for sharp patterns and tailoring |

|

Sustainability |

Ideal for recycled yarns (e.g., plastic bottles) |

Best for organic fibers (e.g., GOTS-certified cotton) |

- Seasonal & Functional Considerations

While knits and wovens work across seasons, here’s how to leverage their strengths:

- Winter Collections:

– Knits: Thermal layers, cozy sweaters, stretchy base layers

– Wovens: Heavy coats (wool blends), durable denim, structured outerwear

- Summer Collections:

– Knits: Lightweight jerseys, breathable activewear

– Wovens: Linen/cotton blends for airflow, crisp button-downs

- Year-Round Essentials:

– Knits: Versatile t-shirts, loungewear, and athleisure

– Wovens: Timeless denim, workwear, and formal separates

- Sustainability & Innovation: Modern Fabric Trends

Both fabrics are evolving with eco-friendly and high-tech innovations:

- Knitting Innovations:

– Recycled Polyester Knits: Made from post-consumer plastic bottles, ideal for sportswear.

– Smart Knits: Moisture-wicking, antimicrobial, or temperature-regulating fibers for performance wear.

- Woven Innovations:

– Organic Cotton Wovens: GOTS-certified for babywear and sustainable basics.

– Water-Repellent Wovens: PFC-free coatings for outdoor outerwear.

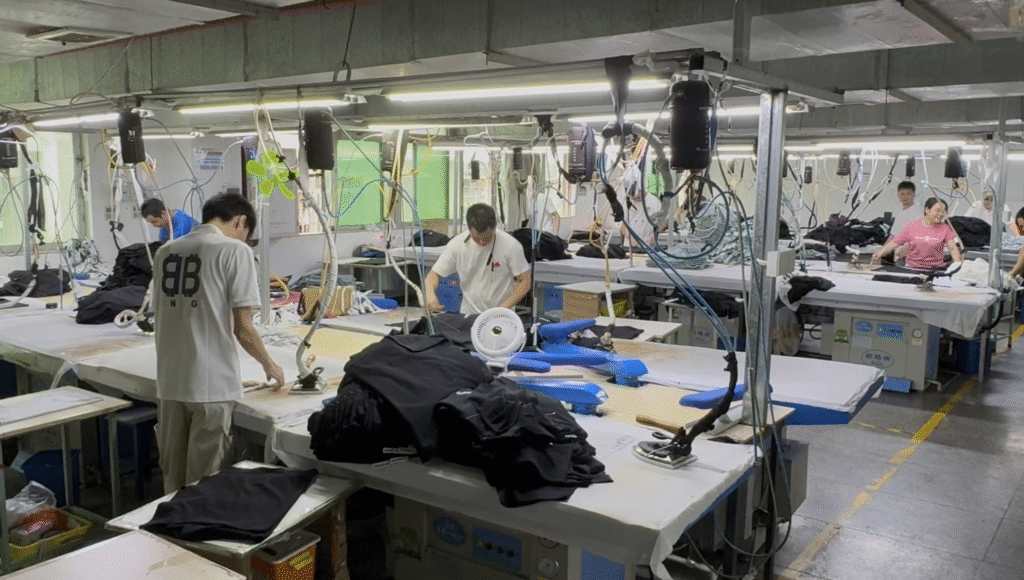

- Production & Cost: What Brands Need to Know

- Knitting Advantages:

– Faster production with minimal waste (perfect for quick fashion turns).

– Lower tooling costs for simple designs.

- Woven Advantages:

– Higher perceived value for structured, durable garments.

– Ideal for complex patterns (jacquards, dobby weaves).

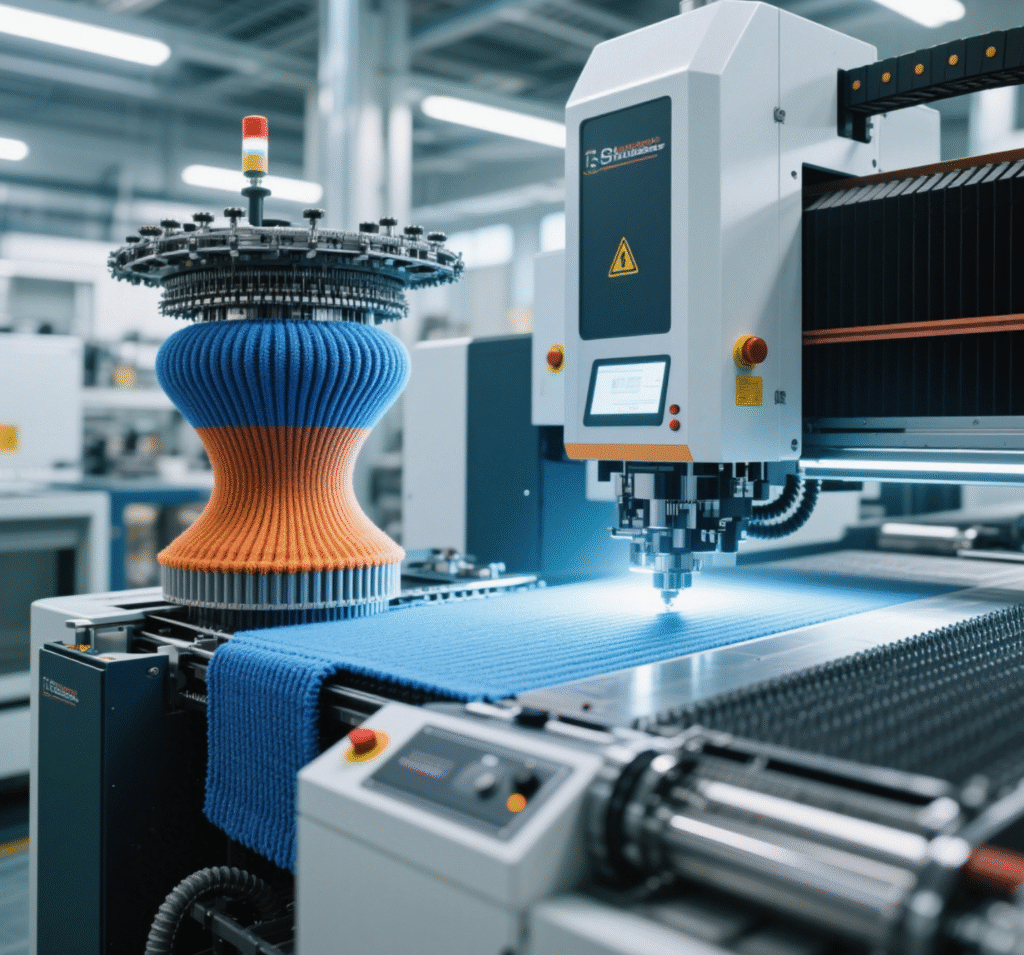

- How PXN Garments Elevates Both Fabric Types

As a leading manufacturer, we specialize in custom solutions for both knitting and woven fabrics:

– Knitting Expertise:

– 3D knitting for seamless garments (reduced waste, enhanced fit).

– certified yarns for kids’ wear and sensitive skin collections.

– Woven Excellence:

– Laser cutting for precise patterns in denim and twill.

– Custom dyeing for Pantone®-matched colors in both fabric types.

Ready to bring your vision to life?

– Request Fabric Swatches: Get

samples of our premium knits and wovens.

– Consult Our Experts: Schedule a call to discuss fabric selection for your collection.

- 9. Conclusion

Knitting and woven fabrics are not rivals—they’re complementary tools in your design arsenal. Knits deliver comfort and versatility, while wovens offer structure and durability. By understanding their unique strengths, you can create collections that balance function, style, and innovation for any season or market.