Welcome to PXN Garments Factory, a 30,000 – sq – m high – volume fashion hub. With 600+ workers, we produce over five million garments yearly, leading in the industry.

Factory Layout

- Production Building

The ground and 1st floors are bustling with activity from our design, pattern – making, and management teams. Designers keep a close eye on the latest fashion trends, putting their creativity on paper through sketches. Meanwhile, managers ensure the smooth operation of the entire production process, fro

m sourcing raw materials to delivering the final products. The showroom stands as a testament to our craftsmanship, displaying a wide range of our past and present collections.

Moving up to floors 3 – 6, you’ll find the heart of our production: the complete manufacturing line. It all starts with the cutting area, where large rolls of carefully selected fabric are laid out on cutting tables. Skilled cutters use precise patterns to transform the fabric into individual pieces, a crucial step that sets the foundation for the entire garment.

Next is the pattern – making and grading section. Pattern – makers employ both advanced software and traditional drafting techniques to create templates for different sizes and styles. These patterns are then graded to ensure a perfect fit for every customer.

After that, the cut pieces move to the sewing area. Here, rows of sewing machines hum in harmony as our experienced seamstresses stitch the pieces together with precision. Our ten hanging production lines transport the garments seamlessly between workstations, maximizing efficiency and reducing manual handling.

Once the basic structure of the garment is complete, it proceeds to the assembly area. Workers here attach buttons, zippers, and other accessories, adding the finishing touches to the design.

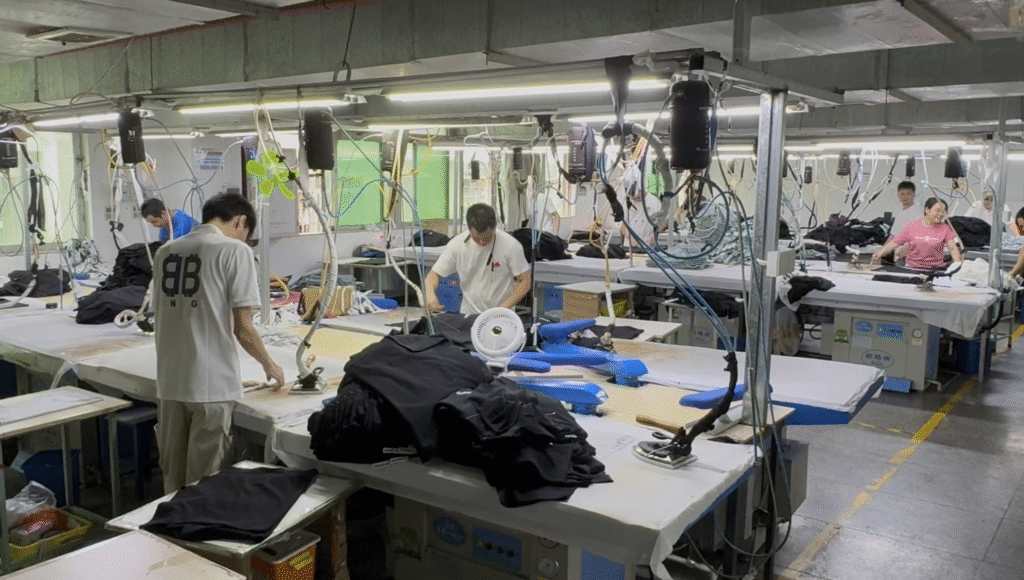

Following assembly, the garments enter the pressing area. Steam irons and pressing machines are used to give the garments a crisp, professional look, removing any wrinkles and setting the shape.

Finally, the garments go through a meticulous inspection process. Workers carefully check for loose threads, uneven seams, and any other defects. Only after passing this rigorous

quality check are the garments considered ready for storage and shipping.

- Warehouse Building

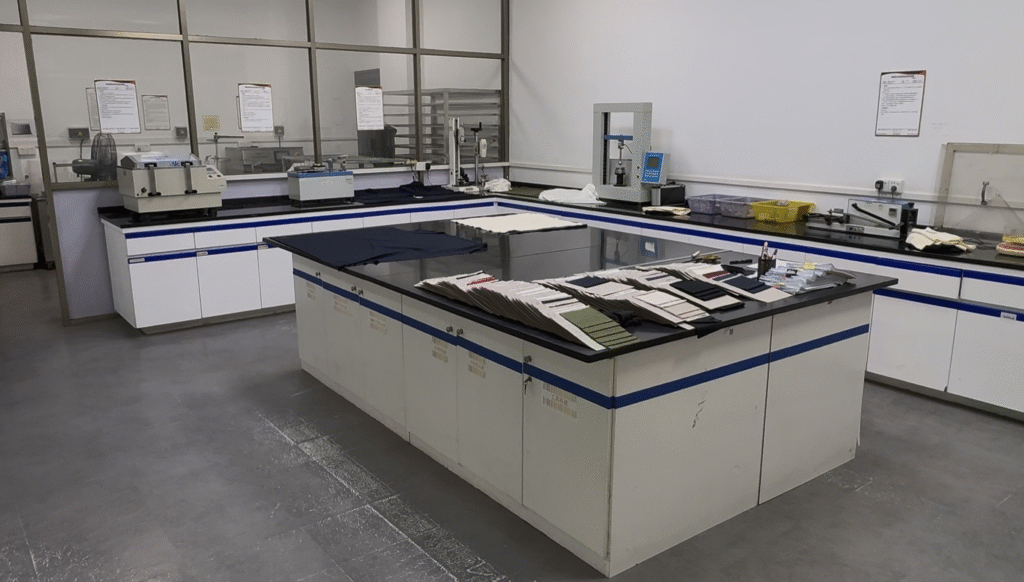

Connected to the production building, the warehouse is a well – organized space dedicated to storing fabric, finished products, and handling shipping. Our fabric storage area is stocked with a wide variety of high – quality fabrics, each carefully selected for its durability, comfort, and aesthetic appeal. The fabric laboratory conducts comprehensive tests on the fabrics to ensure they meet our strict quality standards before being used in production. The finished – product storage area is arranged in an orderly manner, with garments sorted by style, size, and color, making it easy for our logistics team to pick and pack orders efficiently. The shipping area is the final stop, where packed orders are loaded onto trucks and dispatched to our clients around the world.

3. Staff Living Building

Our staff living building is designed to provide a comfortable and relaxing environment for our employees. It features clean and well – furnished dormitories, a canteen that serves a variety of delicious and nutritious meals, a recreation area equipped with entertainment facilities such as a TV, pool table, and reading area, and a fitness center with modern exercise equipment.

Conclusion

PXN Garments Factory is a community united by a passion for high – quality fashion. From the initial design concept to the final product delivery, every step of the process is carefully executed to ensure the highest level of craftsmanship and customer satisfaction. We invite you to visit our factory and witness the magic of garment production firsthand.